|

| June 07, 2016 | Volume 12 Issue 21 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Designing in the cool factor -- Custom Russian choppers use in-house CNC

[All bike images courtesy: BOX39]

How sweet it is when you've got the right tools.

For Vladislav Belyakov, the CEO of BOX39 in St. Petersburg, Russia, the tools that often make all the difference are his in-house design and milling capabilities.

Belyakov pushes design and construction edges from fantasy land into the real world by customizing a bike into something recognizably cool, like an amazing cartoon that you can ride.

Vladislav Belyakov, founder of BOX39, with one of the customized creations he designed and built using products from SolidWorks, ESPRIT, and HAAS UMC-750.

After researching the motorcycle tuning market in the Russian Federation, he discovered that most components for custom bikes had to be imported, which drove up their cost and also their delivery time. The problem was there were very few companies in the country that had the CNC equipment needed to produce high-quality custom components at a reasonable cost.

"Marketing research told us that local custom motorcycle products were made by companies that could not meet high tolerance requirements," Belyakov said. "In most cases, these companies had to perform time-consuming and expensive manual finishing operations. They were also, in many cases, unable to produce complex parts with irregular shapes such as more than one undercut, surface openings, and transitions in different planes."

Belyakov felt that an opportunity existed for a company to apply modern manufacturing methods to custom motorcycle components. "I took a big risk in making a career switch from financial services to motorcycle parts manufacturing in 2011," Belyakov said. "Our first production facility was a rental garage. We designed and put into production our first product within six months of opening our doors on a very tight budget."

BOX39's first production facility.

Since then, BOX39 has developed three more unique products and also developed a thriving business in tuning motorcycles, which involves installation of accessories and painting to change the concept, appearance, and performance of a stock bike into a custom bike. The business has grown rapidly.

"Last year, we decided to automate our production facility and purchase our first CNC machine," Belyakov said. "It allowed us not only to improve the quality and efficiency of producing our existing products, but it also makes it possible in the future for us to develop parts with more complex geometries that can't be produced by conventional methods."

"After spending a long time evaluating different machine tools, we purchased the Haas UMC-750 5-axis universal machining center," said Belyakov. "We believe that using modern equipment and software in the production cycle will reduce the cost and delivery time and also improve the quality and artistic value of the product. This, in turn, will help to expand the overall market for custom motorcycles."

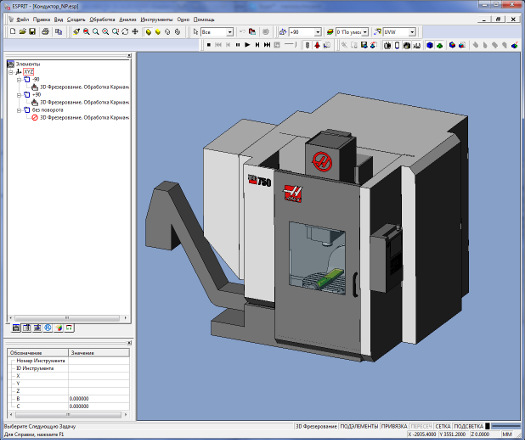

BOX39's HAAS UMC-750 produces a part with a program created with ESPRIT CAM software.

The Haas UMC-750 is a versatile, 5-axis universal machining center with 762 x 508 x 508 mm axis travel and an integrated dual-axis trunnion table. The machine is equipped with an inline direct-drive 40-taper spindle (8,100 or 12,000 rpm) and comes standard with a 40+1 tool side-mount tool changer. The trunnion allows manufacturers to orient parts to almost any angle for five-sided machining or provide simultaneous 5-axis motion for contouring and complex machining. The machine provides +110 and -35 degrees of tilt and 360 degrees of rotation for excellent tool clearance and large part capacity.

Igor Bystrov, who is a designer and technologist for BOX39, recalls the process of choosing CAM software: "After we ordered the machine, cutting tools, and equipment, we started to search for the optimal CAM software. We looked for software capable of programming 3-axis and 5-axis milling that is compatible with our SolidWorks CAD software at a reasonable price. Obviously, we needed a post-processor for our CNC machine. Only two CAM software packages offered in Russia met these requirements. We selected ESPRIT by DP Technology, because it includes a Haas-certified post-processor and HAAS UMC-750 virtual model. Another factor in our decision was the strong training and technical support provided by DP Technology in Russia."

BOX39 uses ESPRIT in programming its HAAS 5-axis machine to build custom motorcycle components.

ESPRIT provides the HAAS UMC-750 with a virtual model and certified post-processor.

In late 2014, BOX39 received its ESPRIT licenses. "We had some experience with our CAD system, but we were not familiar with G-codes and M-codes nor with CAM software," Belyakov said. "Our engineers attended a week-long training course and immediately began creating CNC programs for the 5-axis machine."

"We were able to get up and running almost immediately, because the post-processor worked perfectly from the start, said Belyakov. "Since that point, we have produced many CNC programs and continue to increase our programming skills. Today, we can offer our customers dramatic improvements in quality and productivity relative to other companies in the custom motorcycle components market."

This BOX39 customized Harley-Davidson Softail 2007 bike was the "Best of Show" winner at the 2015 Harley Days festival in St. Petersburg, Russia. Besides the paint and many other design flourishes, BOX39 made the front and rear wheels; swingarm; pulley; rear brake system; frame extension; rear wing; seat; handle bars; front fork; engine covers, rings, and filter; clutch lever handles and footrests, light and stop signal; and exhaust system.

The BOX39 videos are all in Russian, but they are fun to watch and scroll through anyway. Check them out at www.youtube.com/user/TheBox39/videos.

-----------------------

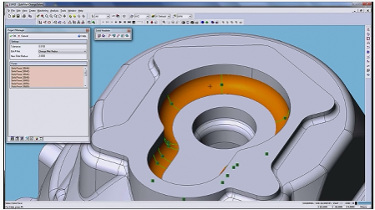

Special: ESPRIT tips for designers prepping files for CAM programming

ESPRIT is capable of importing solid models in a variety of native CAD file formats -- Creo, NX, CATIA, SolidWorks, SolidEdge, Inventor -- as well as 2D drawings, 3D wireframe geometry, surfaces, and STL models. In addition, it supports all standard exchange formats such as STEP, IGES, DXF, etc.

ESPRIT is a versatile CAM software capable of handling virtually any CAD model that needs to be programmed and machined. The data transfer from the CAD system occurs without data loss, and users can also access the CAD features directly in ESPRIT without the need to modify or rebuild geometry.

- ESPRIT FX: ESPRIT FX allows the exchange of design data between ESPRIT and all major CAD systems, including not only the geometry, but also all design features and other parameters that may be used for manufacturing. ESPRIT retains the link to the CAD file, allowing the user to update the model in ESPRIT when the CAD model changes. ESPRIT will read the solid model and adjust accordingly. Any associated tool path will then be automatically readjusted according to all the changes made to the geometry of the part.

- CAD feature manager: When a CAD file is opened in ESPRIT, the reference geometry, sketches, and feature profiles used in the CAD system are also available in ESPRIT's CAD feature tree. Information carried inside sketches can be transferred into ESPRIT perfectly. Users are able to recreate all the reference geometry in ESPRIT.

- Import options: When opening a CAD file, ESPRIT users can set the import options. Specific import options are provided for each type of CAD file such as trim tolerance, create wireframe, load hidden objects, import as solid, and so on. For example, for those CAD models without solids but only surfaces like IGES files, ESPRIT provides a "Stitch Surfaces Into Solid" option to create a solid automatically for IGES files. For another example, ESPRIT supports Autodesk DWG and DXF file formats for both importing and exporting up to the latest version of AutoCAD.

- Assembly: ESPRIT is capable of importing large assemblies from nearly every CAD program without the need for the programmer to modify or rebuild geometry.

- Merge: CAD files can be opened in a new ESPRIT file or merged with an existing ESPRIT file. When files are merged, the information from both files will be combined.

- Feature recognition: CAD designers can group similar operations together for better automatic feature recognition later in ESPRIT to reduce the number of times a part must be repositioned. For example, holes sharing the same diameters can be grouped in the feature design tree of CAD systems so that they can be quickly and easily programmed in ESPRIT.

- Smooth surfaces: An accurate toolpath relies on the accuracy and quality of the underlying model geometry. Sometimes surfaces of solid models have micro-defects that are not noticeable at a glance. ESPRIT allows users to smooth and heal defective surfaces using a smoothing algorithm.

- Models: ESPRIT provides solutions for users to modify their CAD models in a CAM environment to better prepare for machining processes. Users can now edit or remove fillets or even extract a spine curve from fillets as a tool drive curve in machining operations. They can also create one or more surfaces to simplify a solid model by covering holes and openings that will be machined later or not at all. Users can further extend or connect faces so the entire surfaces can be machined as though the openings do not exist. At times, middle faces are required in 5-axis operations. ESPRIT enables users to create a middle surface between two existing solid faces or sets of faces.

- Analysis: Dealing with CAD models in CAM software, analysis tools in ESPRIT help programmers gain a better understanding of their CAD models by identifying curvatures, defects, or normal vectors of faces to machining problems.

Learn about the new features of ESPRIT 2016 now.

Sources: ESPRIT by DP Technology, Box39, HAAS Automation

Published June 2016

Rate this article

View our terms of use and privacy policy